Propelling the construction revolution with silicones

Have you ever wondered how tall buildings withstand extreme conditions in the heights?

Amidst howling winds and the blazing sun, the dazzling 828-meter tall Burj Khalifa in Dubai and the 632-meter-tall Shanghai Tower in China snake their spires up towards infinity.

Their existence has only been made possible in very recent years, thanks to impressive advances in modern technology.

Beyond height, the construction sector has made several extraordinary advances.

Buildings emit fewer greenhouse gases and have become more energy efficient. Their construction uses fewer resources, and they last longer, requiring fewer repairs.

Great strides have been made in earthquake, wind and temperature resistance, making buildings today safer than ever.

Building tomorrow

According to the European Commission, buildings make up 40 percent of the energy use in Europe. The sector is therefore crucial in achieving the goals set out in the Paris agreement, the 2030 climate and energy framework and the circular economy action plan.

At the same time, the construction sector is vital for the European economy - it provides 18 million direct jobs and contributes to more than 5 percent of the EU's GDP.

The solution to the problem is therefore not to construct less, but to construct better.

How were those heights and energy savings achieved, and how will construction continue to improve to meet the needs of tomorrow?

Advancements in the fields of engineering and architecture are of course fundamental, but material science also plays an important role - silicones in particular.

Silicones were first used in construction more than 50 years ago, and are still holding many of those same buildings together today. This inventive chemistry-set revolutionised construction with its multitude of positive attributes.

And silicones innovation did not stop there - every year the silicones industry continues to invest around four percent of its earnings in research and development (R&D).

Silicones have become a key component in the construction industry over the past few decades.The construction sector has made some core achievements to date.

Structural glazing - using silicones - protects and maintains the long-term quality and appearance of a building facade. These facades depend on silicone sealants and glazing to insulate and protect glass panels on buildings from UV rays.

In tall buildings, silicone sealants reinforce the attachment of the glass to the frame - their flexibility and temperature resistant properties help those impressive structures to stay in place.

In addition to enabling construction under extreme conditions, silicones contribute to the circular economy by reducing the amount of materials used in construction.

This, among other things, essentially eliminates the use of mechanical fasteners - prolonging the lifespan of buildings and facilitating energy efficiency.

'Net-zero' emitters

Insulated window glazing that uses silicone sealants reduces greenhouse gas emissions by a factor of 30, compared to what was emitted when they were being made.

The use of silicone additives and coatings can also reduce water ingress by up to 80 percent. Considering that water intake is the predominant reason for biodegradation of buildings, this is quite an achievement.

Silicones also help buildings to become "net-zero" emitters, through building-integrated photovoltaic materials (solar panels) which replace other materials, and provide a renewable energy source where a regular roof, skylight, or facade would have been.

Silicone coatings reduce degradation and help to lengthen the life span of buildings and facades, avoiding costs arising from water or damp damage.

In old buildings and landmarks - such as the statues on Easter Island and the Statue of Liberty in New York - silicones help to reinforce the structures without compromising the integrity of the original materials.

Silicones surfactants on polyurethane panels improve insulation and energy efficiency without compromising surface quality.

Aiding innovative design

BMW Welt in Munich is an example of silicone's unique versatility for building design.

BMW Welt in Munich is an example of silicone's unique versatility for building design.

The versatility of silicones allows for design flexibility, which has brought the world the "Gherkin" and the "Shard" in London, "Gardens by the Bay" in Singapore, BMW Welt in Munich and many others.

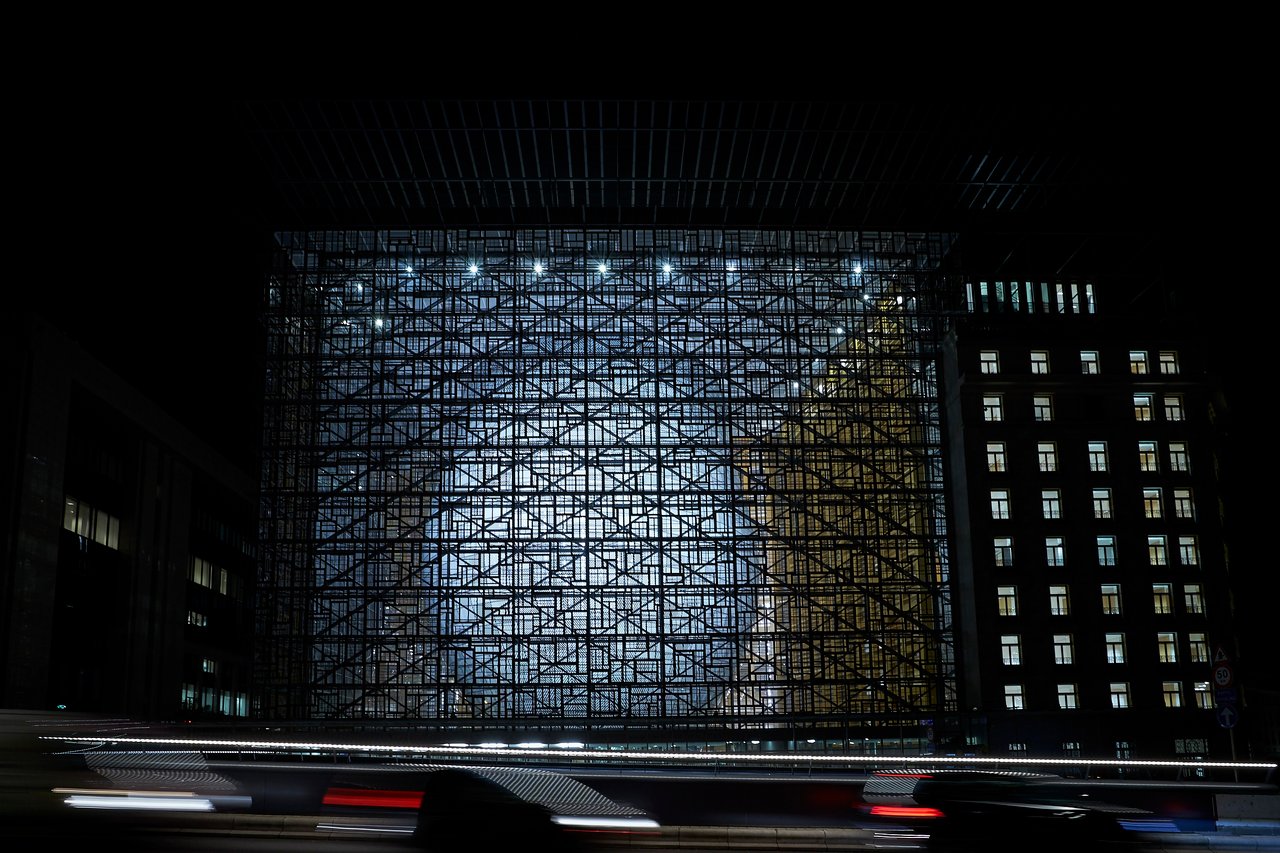

Silicones were also an important component in Brussels' latest architectural feat - the egg-shaped Europa building that houses the EU Council.

Silicones were also an important component in Brussels' latest architectural feat - the egg-shaped Europa building that houses the EU Council.

The future of silicones in architectural and engineering innovations is endless.

A look into the crystal ball shows potential for dynamic glass, next generation lighting and completely transparent bonding materials.

The next time you crane your neck to look up at a tall structure, admire a nearby Unesco heritage building, or drink a cup of tea in your well-insulated house, take a moment to think about the advanced technologies that made it possible.

Disclaimer

This article is sponsored by a third party. All opinions in this article reflect the views of the author and not of EUobserver.Author Bio

Dr. Pierre Germain is the Secretary General of CES - Silicones Europe.

Related articles

Tags

Author Bio

Dr. Pierre Germain is the Secretary General of CES - Silicones Europe.